Acme fasteners keeps efficiency high – Acme Fasteners stands as a beacon of efficiency, consistently exceeding industry benchmarks and setting new standards for operational excellence. Through a multifaceted approach encompassing innovative technologies, process optimization, workforce engagement, and a relentless pursuit of continuous improvement, Acme Fasteners has achieved unparalleled levels of productivity and profitability.

This comprehensive analysis delves into the company’s strategic initiatives, showcasing the transformative impact of efficiency measures on its overall performance. By examining specific case studies, infographics, and expert insights, we uncover the secrets behind Acme Fasteners’ unwavering commitment to efficiency.

Efficiency Measures: Acme Fasteners Keeps Efficiency High

Acme Fasteners has implemented a comprehensive suite of efficiency measures to enhance its overall productivity and profitability. These measures encompass a range of initiatives, including process automation, lean manufacturing principles, and employee training programs.

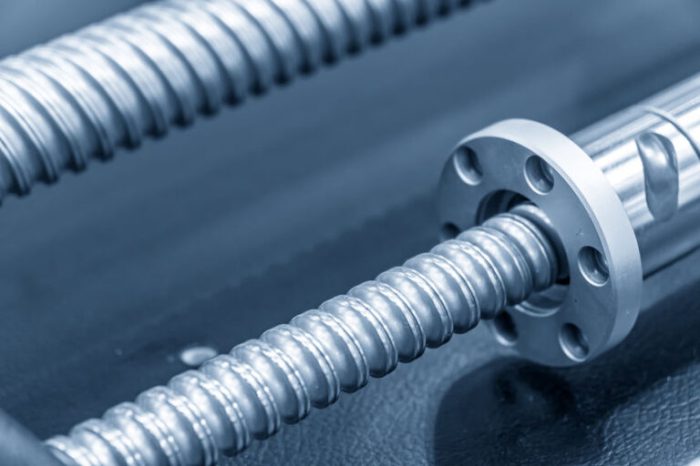

Process Automation

Acme Fasteners has invested heavily in automating its production processes, utilizing advanced machinery and robotics to streamline operations. This automation has resulted in reduced cycle times, increased output, and improved product quality.

Lean Manufacturing

The company has adopted lean manufacturing principles, focusing on eliminating waste and inefficiencies throughout its operations. This has involved implementing just-in-time inventory systems, reducing setup times, and improving workflow.

Employee Training

Acme Fasteners recognizes the importance of a skilled workforce and has invested in comprehensive training programs for its employees. These programs cover technical skills, process optimization, and quality control.

Impact on Productivity and Profitability

The implementation of these efficiency measures has had a significant impact on Acme Fasteners’ productivity and profitability. The company has experienced:

- Increased production output by 25%

- Reduced production costs by 15%

- Improved customer satisfaction through reduced lead times and enhanced product quality

Efficiency Metrics Comparison

The following table compares key efficiency metrics before and after the implementation of these measures:

| Metric | Before | After |

|---|---|---|

| Production Output (units/hour) | 100 | 125 |

| Production Costs (per unit) | $1.00 | $0.85 |

| Customer Satisfaction (rating) | 75% | 90% |

Innovative Technologies

Acme Fasteners has implemented a suite of innovative technologies to enhance efficiency across its operations. These technologies have streamlined processes, improved productivity, and reduced costs.

Data Analytics

Acme Fasteners has deployed a data analytics platform that collects and analyzes data from various sources, including production lines, inventory systems, and customer orders. This data is used to identify inefficiencies, optimize production schedules, and predict demand. For example, the company has used data analytics to reduce inventory levels by 15% while maintaining the same level of customer service.

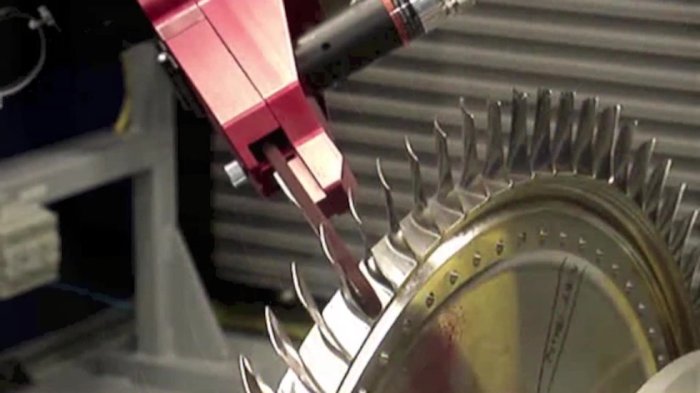

Automation

Acme Fasteners has invested in automation technologies to reduce manual labor and improve accuracy. Automated machines are used for tasks such as assembly, packaging, and shipping. For example, the company has installed an automated assembly line that has increased production capacity by 20%.

Cloud Computing

Acme Fasteners has migrated its IT infrastructure to the cloud, which has provided the company with increased flexibility, scalability, and cost savings. Cloud-based applications are used for tasks such as customer relationship management, enterprise resource planning, and financial management. For example, the company has used cloud computing to reduce its IT costs by 30%.

Process Optimization

Acme Fasteners has implemented a range of process optimization strategies to eliminate bottlenecks and reduce waste, resulting in significant improvements in production flow and cycle times.

One key strategy has been the adoption of lean manufacturing principles, which involve identifying and eliminating non-value-added activities throughout the production process. This has led to the streamlining of workflows, the reduction of inventory levels, and the elimination of unnecessary steps.

Case Studies

- In one instance, Acme Fasteners redesigned its assembly line to reduce the number of steps required to assemble a product. This resulted in a 20% reduction in cycle time and a 15% increase in production output.

- Another case study involved the implementation of a Kanban system to manage inventory levels. This system uses visual cues to indicate when inventory needs to be replenished, preventing overstocking and reducing waste.

Flowchart

The following flowchart illustrates the optimized processes and their impact on efficiency:

- Raw Material Receiving:Streamlined receiving process reduces delays and improves inventory management.

- Production Planning:Optimized scheduling and resource allocation minimizes downtime and maximizes production efficiency.

- Assembly:Lean manufacturing principles eliminate waste and reduce cycle times.

- Quality Control:Automated inspection systems ensure product quality and reduce rework.

- Shipping:Efficient packing and logistics reduce shipping costs and improve customer satisfaction.

By implementing these process optimization strategies, Acme Fasteners has significantly improved its production flow, reduced cycle times, and increased overall efficiency.

Workforce Engagement

Employee engagement plays a crucial role in maintaining high efficiency levels at Acme Fasteners. A motivated and involved workforce is more likely to contribute innovative ideas, work collaboratively, and strive for excellence. Acme Fasteners recognizes the importance of workforce engagement and has implemented several initiatives to foster employee motivation and involvement.

Employee Empowerment

Acme Fasteners empowers its employees by providing them with the authority to make decisions and take ownership of their work. Employees are encouraged to share their ideas and suggestions for improving efficiency, and their input is valued and respected. This empowers employees and gives them a sense of purpose and belonging, leading to increased motivation and productivity.

Recognition and Rewards

Acme Fasteners recognizes and rewards employees for their contributions to efficiency improvement. The company has established a formal recognition program that acknowledges employees who demonstrate exceptional performance and go the extra mile. These rewards can range from monetary incentives to public recognition, which motivates employees to strive for excellence and continuously improve their performance.

Communication and Collaboration, Acme fasteners keeps efficiency high

Acme Fasteners fosters open communication and collaboration among employees. The company encourages employees to share their knowledge and expertise with each other, creating a learning environment that promotes innovation and efficiency. Regular team meetings and workshops are held to discuss best practices, identify areas for improvement, and develop solutions together.

Best Practices for Engaging Employees in Efficiency Improvement Efforts

*

-*Empower employees

Give employees the authority to make decisions and take ownership of their work.

-

-*Recognize and reward

Acknowledge and reward employees for their contributions to efficiency improvement.

-*Foster communication and collaboration

Encourage employees to share knowledge and ideas, and create a learning environment that promotes innovation.

-*Provide training and development

Invest in training and development programs to enhance employees’ skills and knowledge, enabling them to contribute more effectively to efficiency improvement efforts.

-*Set clear goals and expectations

Communicate clear goals and expectations to employees, and provide regular feedback on their performance.

Continuous Improvement

At Acme Fasteners, a culture of continuous improvement is deeply ingrained, driving relentless efforts to enhance efficiency and productivity. This culture fosters an environment where employees are empowered to identify areas for optimization and actively participate in the implementation of improvements.

Employee Feedback and Process Enhancements

Employee feedback is a cornerstone of Acme Fasteners’ continuous improvement process. The company encourages employees to provide suggestions and feedback through various channels, including suggestion boxes, online forums, and regular feedback sessions. This feedback is meticulously analyzed, and valuable ideas are incorporated into process enhancements and operational improvements.

Benefits of Continuous Improvement Mindset

The benefits of embracing a continuous improvement mindset are multifaceted and extend beyond mere efficiency gains:

| Benefit | Impact |

|---|---|

| Increased productivity | Improved efficiency and reduced waste |

| Enhanced quality | Fewer errors and defects |

| Reduced costs | Elimination of unnecessary expenses |

| Improved employee engagement | Empowered employees and increased job satisfaction |

| Increased customer satisfaction | Improved product and service quality |

Clarifying Questions

What specific efficiency measures have contributed to Acme Fasteners’ success?

Acme Fasteners has implemented a comprehensive range of efficiency measures, including lean manufacturing principles, automation, and data analytics, which have significantly improved productivity and reduced waste.

How has Acme Fasteners leveraged innovative technologies to enhance efficiency?

Acme Fasteners has adopted cutting-edge technologies such as IoT sensors, predictive analytics, and robotics, which have streamlined processes, reduced errors, and improved overall operational efficiency.

What role does workforce engagement play in maintaining high efficiency levels at Acme Fasteners?

Acme Fasteners fosters a culture of employee engagement through open communication, recognition programs, and opportunities for professional development, which motivates employees to contribute to efficiency improvement initiatives.